Thermoelectric Generators: The Hidden Power Plant in Your Car

Imagine driving down a long stretch of highway, your car's engine humming steadily. As you cruise along, heat radiates from the engine and exhaust system, seemingly wasted energy disappearing into the air. But what if that heat could be captured and turned into electricity, powering your vehicle's electronics and improving fuel efficiency? This isn't a futuristic dream—it's the promise of automotive thermoelectric generators, a technology that's quietly revolutionizing how we think about energy recovery in vehicles.

The heart of a TEG is a series of semiconductor materials, typically made from bismuth telluride or lead telluride. These materials are arranged in pairs, with one type of semiconductor (n-type) carrying negative charges and the other (p-type) carrying positive charges. When heat flows from the hot side to the cold side of the TEG, it causes charge carriers to diffuse, creating an electrical potential difference.

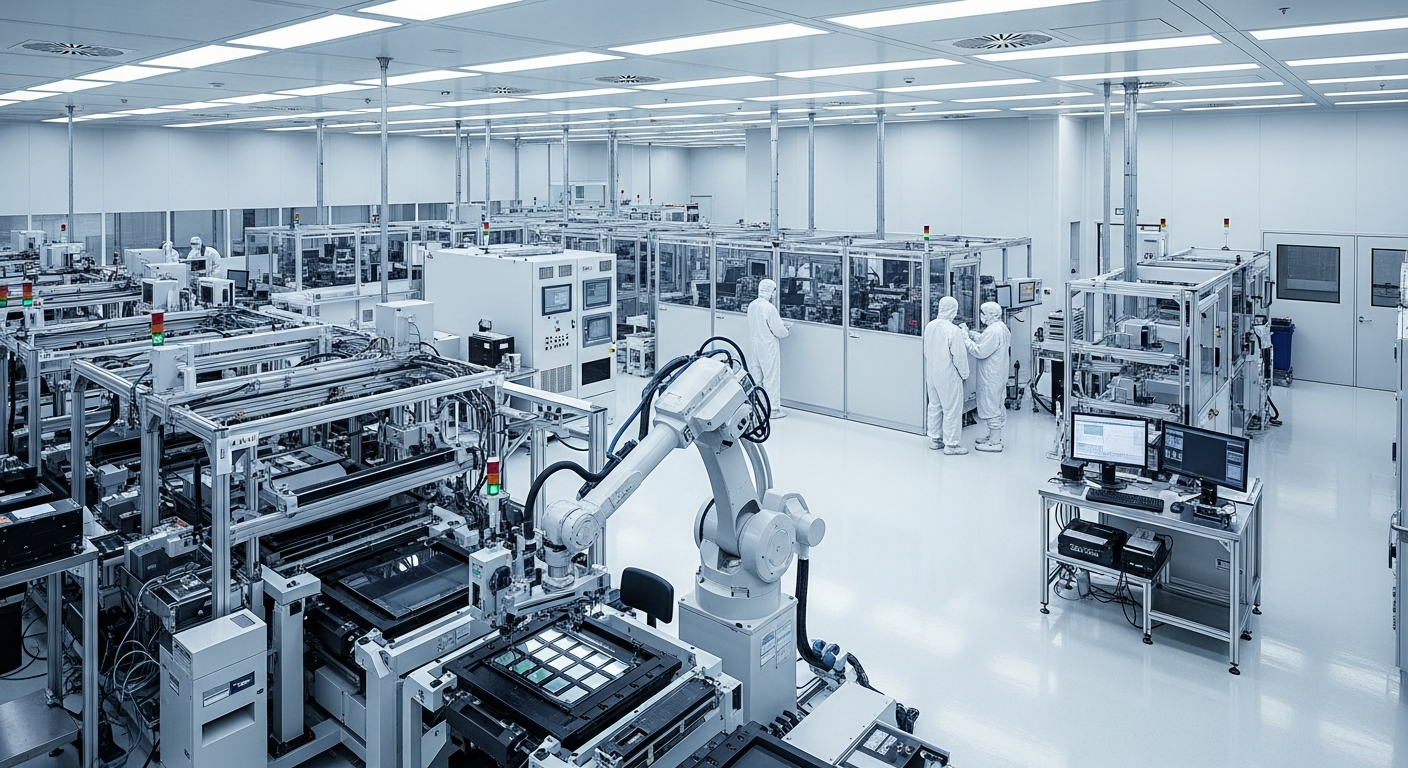

Integration into Automotive Systems

Incorporating TEGs into vehicles presents both challenges and opportunities. The most common placement is in the exhaust system, where temperatures can reach up to 700°C. Here, TEGs can capture a significant amount of waste heat, potentially generating hundreds of watts of electrical power.

However, integrating TEGs isn’t as simple as bolting them onto the exhaust pipe. Engineers must carefully design heat exchangers to maximize thermal transfer while minimizing back pressure on the engine. Additionally, the TEGs must be protected from vibration, corrosive exhaust gases, and extreme temperature fluctuations.

Some automakers are exploring alternative placements, such as in the engine coolant system or even integrated into the engine block itself. These locations offer more stable temperature differentials, potentially increasing the efficiency and lifespan of the TEGs.

Efficiency and Performance Gains

While the concept of TEGs is promising, their efficiency has been a limiting factor in widespread adoption. Current automotive TEGs typically operate at about 5% efficiency, meaning only a small fraction of the waste heat is converted into usable electricity. However, recent advances in materials science and manufacturing techniques are pushing this boundary.

Researchers at Michigan State University have developed new thermoelectric materials that could potentially double the efficiency of TEGs. These materials, based on magnesium silicide and higher manganese silicides, are not only more efficient but also cheaper and more environmentally friendly than traditional thermoelectric materials.

Even with current efficiencies, the benefits of TEGs are notable. By reducing the load on the alternator, TEGs can improve fuel economy by 2-5%. In a world where automakers struggle to eke out every last bit of efficiency, this is a significant gain. Moreover, the electricity generated by TEGs can power auxiliary systems like air conditioning or infotainment systems, further reducing the engine’s workload.

Environmental Impact and Sustainability

The environmental implications of automotive TEGs extend beyond improved fuel efficiency. By recovering waste heat, TEGs reduce the overall thermal footprint of vehicles, potentially mitigating the urban heat island effect in densely populated areas. Additionally, the materials used in TEGs are often recyclable, aligning with the automotive industry’s push towards more sustainable practices.

However, the production of thermoelectric materials does raise some environmental concerns. Many current TEGs rely on rare earth elements or toxic materials like tellurium. As the technology advances, researchers are focusing on developing TEGs from more abundant and eco-friendly materials, such as silicon-germanium alloys or organic thermoelectric materials.

Future Prospects and Challenges

The future of automotive TEGs looks promising, with several major automakers investing in the technology. BMW has been at the forefront, testing TEGs in their vehicles since the early 2010s. Other companies, including Ford, General Motors, and Honda, have also conducted extensive research and development in this area.

One exciting prospect is the combination of TEGs with other energy recovery systems, such as regenerative braking. This holistic approach to energy management could significantly boost overall vehicle efficiency, particularly in hybrid powertrains.

However, challenges remain. The cost of TEGs is still high relative to the efficiency gains they provide, making them difficult to justify in mass-market vehicles. Durability is another concern, as TEGs must withstand the harsh conditions of automotive use over many years.

A Quiet Revolution in Automotive Efficiency

Thermoelectric generators represent a subtle yet significant shift in automotive engineering philosophy. Rather than solely focusing on making engines more efficient, TEGs exemplify a broader approach to vehicle efficiency, where every joule of energy is valued and put to use.

As materials science advances and manufacturing techniques improve, we can expect to see TEGs become more common in vehicles across all segments. While they may never generate headlines like electric powertrains or autonomous driving systems, thermoelectric generators are quietly contributing to a more efficient, sustainable automotive future. The next time you feel the heat radiating from your car’s exhaust, remember: that energy isn’t being wasted—it’s being transformed, powering the quiet revolution of automotive thermoelectric generation.