Nanoengineering: The Hidden Driver of Industrial Miniaturization

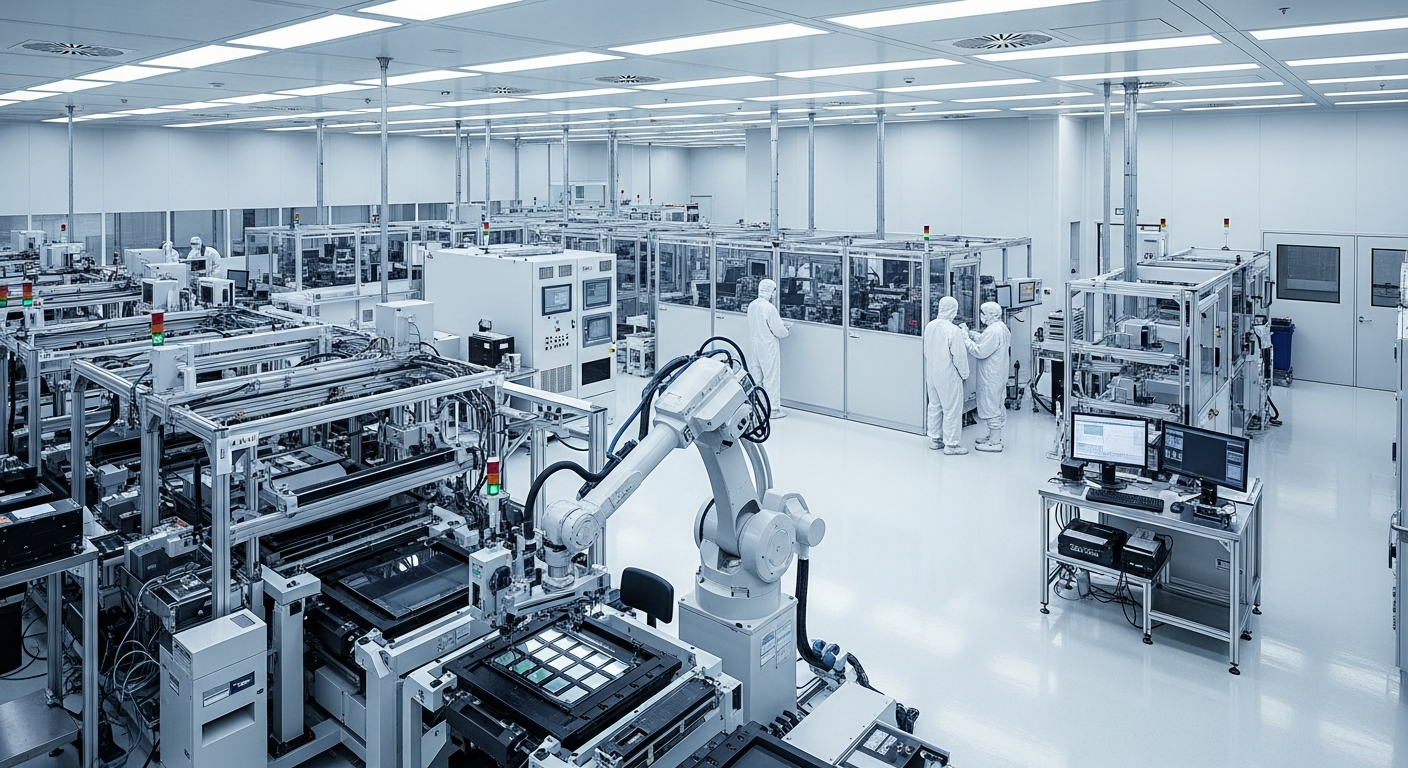

Nanoengineering is revolutionizing industrial processes, enabling unprecedented levels of miniaturization and efficiency. This cutting-edge field is reshaping manufacturing, materials science, and product design across sectors. By manipulating matter at the atomic and molecular scale, nanoengineering is opening doors to innovations that were once thought impossible, driving a new era of industrial capability and competitiveness.

The Nano Revolution in Manufacturing

Nanoengineering is fundamentally changing the manufacturing landscape. Traditional manufacturing methods are being augmented or replaced by nano-enabled processes that allow for unprecedented precision and control. Nano-scale 3D printing, for instance, is enabling the creation of complex structures with features as small as 200 nanometers, opening up new possibilities in fields like microelectronics and medical devices.

Moreover, nanoengineering is enhancing existing manufacturing processes. Nano-coatings can improve the durability and performance of tools and machinery, extending their lifespan and reducing maintenance costs. Nanomaterials are also being used to create more effective filters and membranes, improving efficiency in industries ranging from water treatment to oil refining.

Nanocomposites: Stronger, Lighter, Smarter

One of the most significant impacts of nanoengineering is in the development of nanocomposites. These materials, which incorporate nanoparticles into traditional materials, exhibit properties that far exceed those of their conventional counterparts. For example, carbon nanotube-reinforced polymers can be several times stronger than steel while weighing significantly less.

These nanocomposites are finding applications across industries. In aerospace, they’re enabling the creation of lighter, more fuel-efficient aircraft. In automotive manufacturing, nanocomposites are being used to develop stronger, safer vehicle bodies that also improve fuel economy. Even in consumer goods, nanocomposites are enhancing product performance, from more durable sports equipment to longer-lasting packaging materials.

Nano-enabled Sensors and Smart Materials

Nanoengineering is also at the forefront of developing advanced sensors and smart materials. Nano-sensors can detect changes at the molecular level, enabling more precise monitoring and control in industrial processes. These sensors are being integrated into manufacturing systems to improve quality control, reduce waste, and enhance overall efficiency.

Smart materials that can respond to environmental stimuli are another exciting development. Self-healing materials that can repair minor damage without human intervention are being developed for use in everything from electronic devices to building materials. Shape-memory alloys that can return to their original form after deformation are finding applications in aerospace and medical industries.

Energy Efficiency and Sustainability

Nanoengineering is playing a crucial role in improving energy efficiency and sustainability in industrial processes. Nano-catalysts, for instance, are enhancing chemical reactions, reducing energy requirements and waste in manufacturing processes. In the energy sector, nanoengineered materials are improving the efficiency of solar cells and batteries, driving the transition to renewable energy sources.

Furthermore, nanoengineering is enabling more efficient use of resources. Nano-filtration technologies are improving water purification processes, while nano-enabled recycling techniques are making it possible to recover and reuse materials that were previously considered waste. These advancements are not only reducing the environmental impact of industrial operations but also opening up new avenues for cost savings and resource optimization.

Challenges and Future Directions

While the potential of nanoengineering in industrial applications is immense, it’s not without challenges. The complexity of working at the nanoscale presents significant technical hurdles. Ensuring the consistency and scalability of nano-enabled processes remains a key focus area for researchers and engineers.

There are also concerns about the potential health and environmental impacts of nanomaterials. As these materials become more prevalent in industrial processes and consumer products, ensuring their safe use and disposal is paramount. This has led to increased focus on developing regulations and standards for nanotechnology in industrial applications.

Looking ahead, the integration of nanoengineering with other emerging technologies like artificial intelligence and quantum computing promises to unlock even greater potential. As our ability to manipulate and control matter at the nanoscale improves, we can expect to see even more revolutionary applications in industrial processes and product design.

Practical Insights for Industrial Adoption of Nanoengineering

• Start small: Begin by identifying specific processes or products where nanoengineering could provide immediate benefits.

• Collaborate: Partner with research institutions or nanotechnology startups to access cutting-edge expertise and technologies.

• Invest in training: Develop your workforce’s skills in nanotechnology to prepare for future integration.

• Monitor regulations: Stay informed about evolving regulations and standards related to nanomaterials and processes.

• Consider lifecycle: Evaluate the full lifecycle impact of nano-enabled products, from production to disposal.

As nanoengineering continues to advance, it’s clear that its impact on industrial practices will only grow. From enhancing material properties to enabling new manufacturing processes, this field is driving a wave of innovation that’s reshaping industries. For business leaders and industrial operators, understanding and leveraging the potential of nanoengineering will be crucial in maintaining competitiveness and driving future growth. As we move forward, the invisible world of the nanoscale will increasingly shape the visible world of industrial production and technological advancement.