Agile Inventory Management: Optimizing Stock in Dynamic Markets

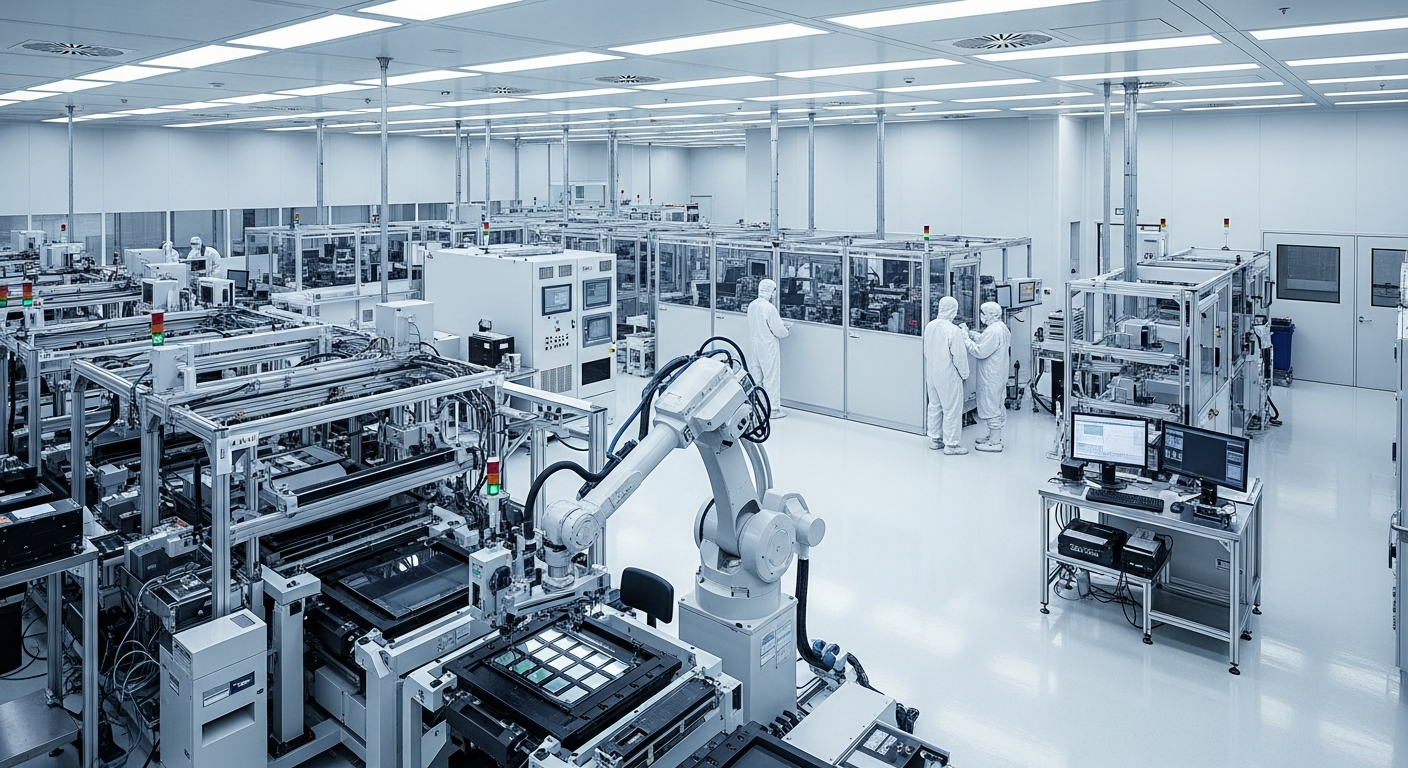

In today's fast-paced business environment, maintaining optimal inventory levels is a critical challenge for companies across industries. Agile inventory management, a cutting-edge approach to stock control, has emerged as a powerful solution for businesses grappling with fluctuating demand and supply chain uncertainties. This innovative strategy enables companies to adapt swiftly to market changes, minimize carrying costs, and maximize customer satisfaction.

The Evolution of Inventory Management

Inventory management has come a long way from the days of manual stock counts and intuition-based ordering. Traditional methods often relied on historical data and fixed reorder points, leading to inefficiencies and missed opportunities. As markets became more volatile and consumer expectations grew, businesses realized the need for a more dynamic approach to inventory control.

The advent of just-in-time (JIT) inventory in the 1970s marked a significant shift towards leaner operations. However, JIT’s rigidity sometimes left companies vulnerable to supply chain disruptions. Agile inventory management builds upon these foundations, incorporating advanced technologies and flexible strategies to create a more resilient and responsive system.

Key Principles of Agile Inventory Management

Agile inventory management is built on several core principles that enable businesses to maintain optimal stock levels in the face of uncertainty:

-

Real-time visibility: Utilizing advanced tracking systems and IoT devices to monitor inventory levels, location, and movement in real-time.

-

Demand forecasting: Employing sophisticated algorithms and machine learning to predict future demand based on historical data, market trends, and external factors.

-

Dynamic reordering: Adjusting reorder points and quantities automatically based on current demand, lead times, and supply chain conditions.

-

Cross-functional collaboration: Breaking down silos between departments to ensure seamless communication and coordination in inventory decisions.

-

Continuous improvement: Regularly analyzing performance metrics and implementing iterative improvements to refine the inventory management process.

Implementing Agile Inventory Management

Transitioning to an agile inventory management system requires careful planning and execution. Here are the key steps to successful implementation:

-

Assess current inventory processes: Conduct a thorough audit of existing inventory management practices, identifying pain points and areas for improvement.

-

Invest in technology: Implement robust inventory management software that offers real-time tracking, predictive analytics, and integration with other business systems.

-

Train staff: Provide comprehensive training to employees on new systems and processes, emphasizing the importance of data accuracy and cross-functional collaboration.

-

Establish KPIs: Define clear key performance indicators (KPIs) to measure the success of the agile inventory management system, such as inventory turnover ratio, stockout rate, and carrying costs.

-

Start small and scale: Begin with a pilot program in a specific product category or location before rolling out the system across the entire organization.

Benefits of Agile Inventory Management

Implementing an agile inventory management system can yield significant benefits for businesses:

-

Reduced carrying costs: By maintaining optimal stock levels, companies can minimize storage expenses and reduce the risk of obsolescence.

-

Improved cash flow: Lower inventory levels free up capital that can be invested in other areas of the business.

-

Enhanced customer satisfaction: Agile inventory management helps ensure product availability, reducing stockouts and improving order fulfillment rates.

-

Increased flexibility: The ability to quickly adjust to market changes and demand fluctuations improves overall business agility.

-

Data-driven decision making: Access to real-time inventory data enables more informed and strategic decision-making across the organization.

Challenges and Considerations

While agile inventory management offers numerous benefits, it also presents some challenges:

-

Initial investment: Implementing new technologies and training staff can require significant upfront costs.

-

Data quality: The effectiveness of agile inventory management relies heavily on accurate and timely data input.

-

Cultural shift: Transitioning to an agile mindset may require overcoming resistance to change within the organization.

-

Supply chain complexity: For businesses with complex supply chains, implementing agile inventory management across all tiers can be challenging.

-

Balancing agility with stability: It’s crucial to find the right balance between responsiveness and maintaining a stable inventory base.

Practical Strategies for Agile Inventory Success

• Implement ABC analysis to prioritize inventory management efforts

• Utilize cycle counting for more frequent and accurate stock checks

• Develop strong supplier relationships to improve lead times and flexibility

• Leverage demand sensing technologies to capture real-time market signals

• Establish safety stock levels based on demand variability and lead times

• Implement vendor-managed inventory (VMI) for critical components

• Use scenario planning to prepare for potential supply chain disruptions

In conclusion, agile inventory management represents a significant leap forward in the quest for optimal stock control. By embracing real-time data, predictive analytics, and flexible strategies, businesses can navigate the complexities of modern markets with greater confidence and efficiency. While challenges exist, the benefits of reduced costs, improved customer satisfaction, and increased agility make it a compelling solution for companies looking to stay competitive in today’s dynamic business landscape. As markets continue to evolve, agile inventory management will undoubtedly play a crucial role in shaping the future of supply chain operations.