Adaptive Manufacturing: Reshaping Production in Volatile Markets

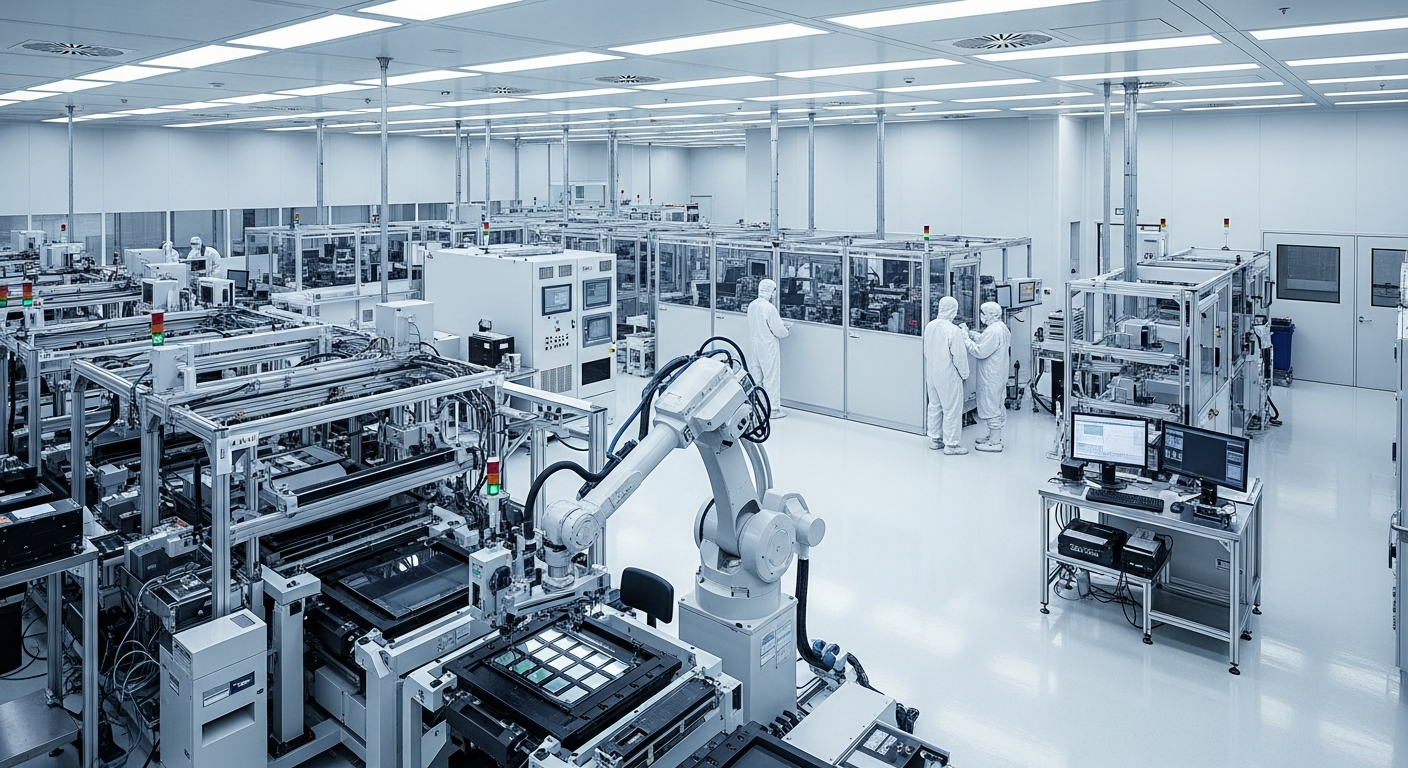

Navigating market volatility has become a critical challenge for manufacturers worldwide. Adaptive manufacturing, a groundbreaking approach to production, is emerging as a powerful solution. This innovative strategy enables businesses to swiftly adjust their operations in response to rapidly changing market demands, supply chain disruptions, and evolving consumer preferences. By embracing flexibility and agility, adaptive manufacturing is revolutionizing how companies approach production, inventory management, and customer satisfaction.

The Evolution of Manufacturing Flexibility

The roots of adaptive manufacturing can be traced back to the early 20th century when Henry Ford introduced the moving assembly line. This innovation dramatically increased production efficiency but lacked flexibility. As consumer demands diversified, manufacturers recognized the need for more adaptable production methods. The introduction of lean manufacturing in the 1950s by Toyota marked a significant step towards flexibility, focusing on minimizing waste and improving efficiency.

In recent decades, the advent of computer-integrated manufacturing (CIM) and flexible manufacturing systems (FMS) laid the groundwork for today’s adaptive manufacturing. These technologies introduced programmable machines and modular production units, allowing for quicker changeovers between product types. However, it wasn’t until the integration of advanced data analytics, artificial intelligence, and the Internet of Things (IoT) that truly adaptive manufacturing became possible.

Key Components of Adaptive Manufacturing

At the heart of adaptive manufacturing lies a network of interconnected systems and strategies. Advanced sensors and IoT devices collect real-time data from every aspect of the production process. This data is then analyzed using sophisticated AI algorithms to identify patterns, predict potential issues, and optimize operations. Cloud computing enables seamless data sharing across the entire supply chain, facilitating rapid decision-making and collaboration.

Modular production lines form another crucial component of adaptive manufacturing. These flexible units can be quickly reconfigured to produce different products or accommodate changes in production volume. 3D printing and additive manufacturing technologies further enhance adaptability by enabling on-demand production of parts and prototypes, reducing lead times and inventory costs.

Benefits and Challenges of Implementation

Implementing adaptive manufacturing offers numerous advantages. Companies can respond more quickly to market changes, reducing the risk of overproduction or stockouts. This agility leads to improved customer satisfaction, as businesses can offer greater product customization and faster delivery times. Additionally, the data-driven nature of adaptive manufacturing allows for continuous improvement in quality and efficiency.

However, transitioning to an adaptive manufacturing model is not without challenges. The initial investment in technology and infrastructure can be substantial. Workforce training is crucial, as employees need to develop new skills to operate and maintain advanced systems. There’s also the challenge of integrating legacy systems with new technologies, which can be complex and time-consuming.

Real-World Success Stories

Several companies have successfully implemented adaptive manufacturing principles, reaping significant benefits. One automotive manufacturer implemented a modular production system that allowed them to produce multiple car models on the same line. This flexibility enabled them to adjust production volumes quickly in response to changing demand, resulting in a 15% increase in overall efficiency and a 20% reduction in inventory costs.

A consumer electronics company leveraged adaptive manufacturing to introduce rapid product customization. By implementing flexible assembly lines and advanced 3D printing capabilities, they reduced new product introduction times by 40% and increased customer satisfaction scores by 25%. These examples illustrate the transformative potential of adaptive manufacturing when successfully implemented.

Future Trends and Innovations

As technology continues to evolve, adaptive manufacturing is poised for further advancement. The integration of 5G networks promises to enhance real-time data processing and communication, enabling even faster response times. Edge computing will bring computational power closer to the production floor, reducing latency and improving decision-making speed.

Advancements in materials science are also set to play a crucial role. Smart materials that can change properties on demand could revolutionize product design and manufacturing processes. Additionally, the development of more sophisticated AI and machine learning algorithms will further enhance predictive capabilities, allowing manufacturers to anticipate market changes and adjust operations proactively.

Strategies for Successful Adoption

• Conduct a thorough assessment of current manufacturing processes to identify areas for improvement

• Invest in employee training and development to build a skilled workforce capable of managing adaptive systems

• Start with pilot projects to test and refine adaptive manufacturing concepts before full-scale implementation

• Foster a culture of innovation and continuous improvement throughout the organization

• Collaborate with technology partners and industry experts to stay at the forefront of adaptive manufacturing trends

In conclusion, adaptive manufacturing represents a paradigm shift in production strategies, offering a powerful solution to the challenges of market volatility. By embracing flexibility, leveraging advanced technologies, and fostering a culture of innovation, manufacturers can position themselves for success in an increasingly unpredictable business landscape. As this approach continues to evolve, it will undoubtedly play a crucial role in shaping the future of industrial production.